Water Distribution Systems

Laboratory network

The laboratory network of Babol Noshirvani University of Technology was designed and built in May 2019. Since this network has a variable height figure, it can evoke conditions close to the real state of water supply networks. This network consists of three square rings measuring 2 meters by 2 meters. The number of main pipes is 12 and the number of nodes is 10. The used pipelines are made of polyethylene PE80 with a nominal diameter of 50 mm and a wall thickness of 3.7 mm. This network has four inclined branches with a slope of 0.25 in the transverse direction. To keep the inlet head constant, an air tank is used, which is installed on top of the tank of an overflow pipe. In this situation, it is possible to use higher flow rates but with more limited fluctuations.

Schematic of Equipments and Laboratory network flow path

Some of the important features of this network are:

*The water level in the tank is about 7 meters above the end of the circular network.

*By adjusting the outlet valve, transient current is formed in the network.

*The lengths of the tubes are equal with good precision; Therefore, their Courant numbers will be equal.

*The location of the manifold for installing valves and sensors is located on the point of the longitudinal step of the Courant number.

*The ability to create a fixed head without noise

*The ability to apply different headers to the network

*Being circular, similar to most urban networks

Introducing the research projects carried out by the Water Transfer Systems Unit

1.Methods of increasing lifespan and optimizing energy consumption in drinking water pumping stations in Mazandaran villages

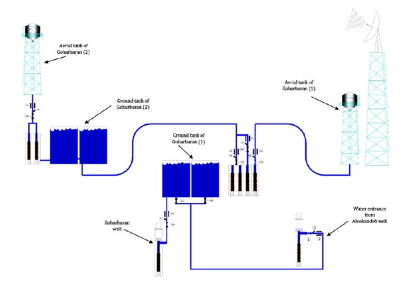

This research project in 2013 and in line with the optimization of energy consumption in five water pumping stations in Sari city includes; Goharbaran phase 1 and 2 and Moalemkola, Pahnekola and Khazarabad Central stations were carried out with the aim of developing effective optimization solutions in all covered stations and with the support of Mazandaran Rural Water and Sewerage Company. The content of this

The project includes field study, identification of existing systems and review of various optimization methods of water pumping stations, analysis and audit of energy costs, etc. in four reports and a total of 704 pages were presented to Abfar. Also, the results obtained from the three methods of using engine speed controllers, selecting the appropriate pump arrangement, and transferring load from peak consumption hours (with a systemic perspective), were sent and approved in the form of four scientific articles to publications, conferences and conventions related to the subject.

2- A comprehensive study of wastage and non-revenue water in the subscribers of rural water and sewage company in Mazandaran province (Babol as city pilot)

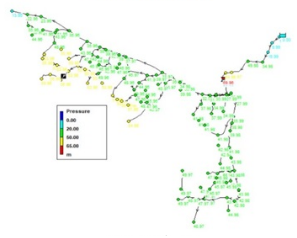

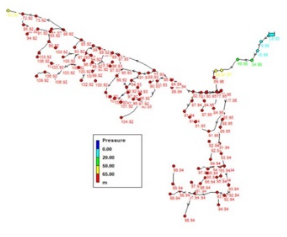

This project was carried out in 2017 with the aim of a comprehensive study to express the types of leakage detection methods in the world, as well as the application of smartening the network and determining the optimal points. Shirdarkola and Gavankla village complex, Babolkanar section of Babol city with 1521 subscribers, 1.88 km of transmission line from well to tank and 35 km of water supply network with an average production flow rate of 13.8 and an average sales flow rate of 7 liters per second, with 47% wastage, as a research pilot selected. Based on the data, these villages, having about 2 fractures per day, impose more than 70 million Tomans (in 2018) to fix the fracture, and on the other hand, the cost of producing wasted water is over 700 million Rials per year.

|

executive actions |

Office and research activities |

|

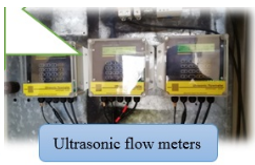

1. Implementation of the collector at the outlet of the tank, installation of flowmeter and its proper distribution between consumption zones 2. Installation of 2 pressure relief valves for areas with excess pressure 3. Replacing the pipe with size 110 polyethylene in the downstream part of Shirdarkla village with a length of approximately 400 meters and installing a valve at the entrance of the main alleys to manage water distribution. 4. Monitoring of the route in zone A (upstream area of Shirdarkola village) and control of the circular network has been established 5. Providing proper pressure in zone A by increasing the head by 10 meters |

1.Establishing isolation areas for investigation (DMA) and investigation of the amount of production and consumption and specifying the problems of each zone. 2. Presenting the algorithm of how to correctly replace the meter of home subscribers 3. Hydraulic analysis of zones with different scenarios with software EPANET.2 4. Correcting the map of the project billet and determining the points of valves and important connections of the network 5. Providing a fracture density map and determining the priority of pipe replacement and corrective measures 6. Presenting the daily and monthly consumption patterns of the rural sector |

Comparison of the system before and after the implementation of the operation

|

After running the operation |

Before executing the operation |

|

Average pressure: 41 meters Number of fractures: 3 events per month Water loss rate: 1.4 liters per second |

Average pressure is 86 meters Number of fractures: 38 cases per month Water loss rate: 4 liters per second |

890 million Rials annual cost reduction

|

|

|